Dew point meters detect humidity directly. Measure the dew point (frost) temperature by cooling a mirror in the sample’s humid air until dew droplets (or ice crystals) appear on it. High humidity measurement accuracy requires a smooth mirror surface, a precise temperature control system, and a sensitive optical dew droplet (ice crystal) detecting device. During use, the sample air pipe must be kept clean so that contaminants don’t soak up or release moisture, which would throw off measurements.

Why is dew point measurement important for the process industry?

1) Process safety and protective equipment

Excess moisture in pipes can cause corrosion, equipment failure, leaks, and explosions. The cold can jam pipes with ice. Humidity control protects personnel and reduces unscheduled maintenance.

2) Quality

Moisture ruins many goods. In metallurgy, the furnace moisture level must be carefully regulated to prevent product weakness. In pharmaceutical manufacturing, the powder must be kept dry to avoid agglomeration. Low humidity prevents chemical reactions in refineries. Moisture must be monitored in high-purity gas processes.

3) Efficiency

Dryer heat is expensive for many procedures. Monitoring the dryer’s output stops the cycle when it’s completed.

4) Meet requirements

International quality standards include moisture or dew point levels. Example: EASEE Gas Quality Standard.

Dew point meter principle

The sensor measures micropore water molecules. The number of water molecules entering the micropores depends on the gas’s moisture content and overall pressure. The moisture content can be estimated if the analyzer knows the total gas pressure.

Dew point meter types

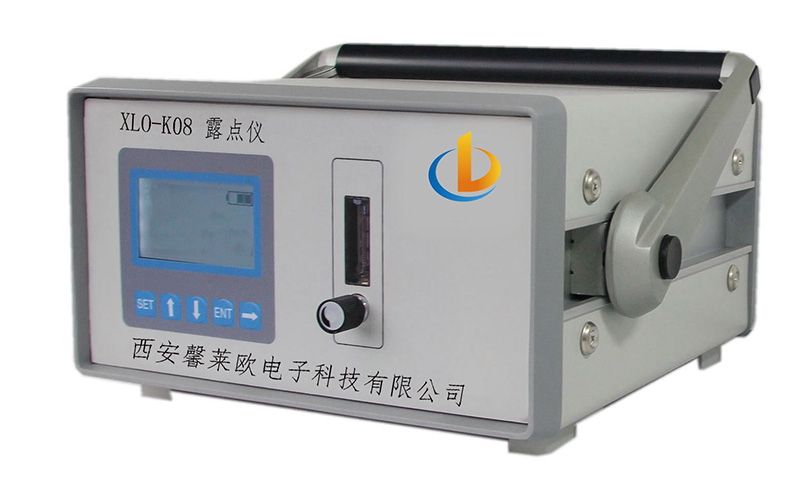

- Mirror Dew point meter

Different gases condense at different temperatures on the mirror. The exposed layer is recognized and the dew point is presented using photoelectric detection technology. Semiconductor, liquid nitrogen, and high-pressure air are used to cool mirrors. Mirror-type Dew point meters measure directly. This Dew point meter ensures accurate dew detection, high mirror cooling efficiency, and precise condensation temperature measurement. The current accuracy of the dew point is 0.1 °C, and the overall accuracy is 0.5 °C.

- Electric sensor type Dew point meter

Form capacitance or resistance with hydrophilic or hydrophobic material. The dielectric constant or conductivity will alter once water-containing gas goes through. By measuring capacitance or resistance, you can determine the gas’s moisture level. This dew point sensor analyzer uses the dew point unit system. The upper z precision is 1.0 °C (dew point) and the general accuracy is 3 °C.

- Electrolytic Dew point meter

An electrolytic micro-moisture meter is made from phosphorus pentoxide and other compounds that absorb water and break down into polar molecules.

- Crystal oscillation type Dew point meter

The oscillation frequency of a wetted crystal can be used to create a crystal oscillation Dew point meter. This technology is still immature. Similar items overseas are inaccurate and expensive.

- Infrared Dew point meter

The infrared Dew point meter is created using water’s absorption in the infrared band. This instrument has trouble measuring low dew point due to the infrared detector’s poor peak detection rate and interference from other gas components. This is a new method for non-contact online monitoring of ambient gas moisture content.

- Semiconductor sensor

When a water molecule penetrates the voids of a semiconductor lattice, it resonates with the charged lattice, and its resonance frequency is proportional to the quantity of water molecules. The resonance of water molecules can release free electrons from the semiconductor junction, increasing lattice conductivity and decreasing resistance. This Dew point meter can measure trace moisture at-100 °C.

How to choose a Dew point meter

There are different ways to measure the dew point. When buying, you should think about not only how well it works and how much it costs, but also how it will be used, what kind of gas it will measure, and how corrosive it is.

Here are some suggestions:

1) The dew point transmitter is compact and inexpensive.It can be used for a wide range of safety and hazardous applications, such as Easidew PRO IS, Easidew PRO XP, SF72, SF82, etc.

2) Portable Dew point meters can be used for testing and making sure things are right. It can be used to check the readings from an on-line moisture analyzer or to do spot checks at different points in the process, such as to find leaks. For example, MDM300, MDM100, MDM50, Easidew Portable, and so on.

3) Sample handling and moisture analyzers are often (but not always) certified for use in hazardous areas. This is also true of process moisture analyzers. Most of the time, these units are made to be used in oil refineries or plants that process natural gas. For example, CDP301, Condumax II, QMA601, QMA401, etc.

4) A chilled mirror Dew point meter measures how much condensation actually forms on surfaces that control temperature. They are accurate and don’t move much. Even though many models are used in the lab, they can also be used to keep an eye on industrial processes like metallurgical processes, such as Opt401, S8k-100, S8k Remote, etc.

5) Continuous online detection: if you don’t need too much accuracy.

6) Measuring how safe natural gas is from exploding: Explosion-proof treatment is needed in the petrochemical and natural gas industries, so a Dew point meter that is intrinsically safe and explosion-proof is needed.

7) Dew point measurement in the gas-air separation industry: We know that the air separation industry usually needs a very low amount of moisture, and the dew point is below -70 °C (1 ppm level). Since you can’t measure gas below -80 °C, it’s best to choose a Dew point meter that works on the principle of capacitance.

Suggestions for manufacturers to consider when designing a Dew point meter

The dew point sensor’s affecting factors include refrigeration, dew point measurement, condensation detection, and mirror temperature control. Capacitive, resistive, and cooled mirror sensors measure the dew point.

Several elements should be considered while building a Dew point meter, including refrigeration, dew point temperature measurement, condensation detection, and mirror temperature control. Only by addressing the above elements can a high-performance instrument be designed.

1. Mechanical, compressed air, liquefied gas or dry ice, and thermoelectric are common refrigeration methods. Thermoelectric refrigeration is an easy and precise control system that has more advantages than others and is the future of Dew point meters.

2. Dew point is determined using thermocouple, thermistor, and pin resistance temperature sensors. The thermistor is sensitive but unstable, like a thermocouple. The uranium resistance temperature sensing element offers a wide linear range, high precision, good stability, and a powerful output signal. High-precision Dew point meters measure temperature via pin resistance.

3. Dew point condensation can be detected visually, photoelectrically, or piezoelectrically. When a Dew point meter user demands accuracy better than °, they utilize a high-precision photoelectric measurement technology. However, it has drawbacks like slow response, easy lag, and dew point adjustment. Piezoelectric detection can detect supercooling through pressure.

FAQ:

- What is dew point?

A dew point is the passage of a gas with an undetermined water vapor concentration over a temperature-controlled surface. A dew point temperature is the temperature at which condensation forms. The dew point measures gas moisture.

- What effect does pressure have on the dew point?

Gas pressure increases the dew point temperature. At 1013.3 mbar, the dew point is -10°C. The water vapor partial pressure (e) is 2.8 mbar. If you double the air’s total pressure to 2026.6 mbar, Dalton’s equation says the water vapor’s partial pressure will double to 5.6 mbar. 5.6 mbar corresponds to a -1°C dew point, hence raising air pressure will likewise increase the dew point. Compressing air to atmospheric pressure lowers the partial pressure of all gas components, including water vapor, lowering the dew point temperature. P1/P2 = e1/e2 for total pressure and water vapor partial pressure.

- How to ensure a fast response time of the Dew point meter?

When an ambient dew point probe is inserted into a -40 °C compressed air line, it can take hours to days for traditional sensors to establish equilibrium. Other capacitive sensor systems dry the hygroscopic layer of the sensor by letting dry process air flow over it.

Capacitive polymer sensors with scavenging are better. When the sensor detects a dew point drop (10°C or greater), it heats up and begins a purging cycle. These pulls water out of the polymer layer, drying the sensor in 5-6 minutes.

- Can evaporation temperature be used instead of dew point pressure?

In a refrigerated dryer, evaporating temperature (evaporating pressure) does not replace compressed air’s pressure dew point. In an evaporator with a limited heat transfer area, there is a non-negligible temperature difference (up to 46 °C) between the evaporation temperatures of the compressed air and the refrigerant during the heat exchange process, and the compressed air can be cooled above the refrigerant’s evaporating temperature.

The “gas-water separator” between the evaporator and precooler is not 100% efficient, so small water droplets with unstable separation penetrate the precooler with the airflow, causing “secondary evaporation.” The dew point rises as compressed air vaporizes. The temperature at which the refrigerant evaporates is always lower than the “pressure dew point” of the compressed air.

- In what situations can temperature measurement be used instead of “pressure dew point”?

In the industrial field, it’s difficult to make the Dew point meter sample air at “pressure dew point” sporadically, and imperfect test settings impair test findings. When standards aren’t rigorous, thermometers are used to approximate compressed air’s “pressure dew point.” The compressed air is forcedly cooled by the evaporator before entering the precooler through the “gas-water separator,” and the separation efficiency of the condensed water cannot reach 100%. When the condensed water from the precooler and evaporator is well discharged, it enters the “gas-water separator,” and the condensed water that needs to be removed is a small percentage of the overall amount.

This method for determining “pressure dew point” isn’t extremely inaccurate. The temperature measurement point should be at the end of the refrigerated dryer’s evaporator or in the “air-water separator” for measuring compressed air’s “pressure dew point.” Because compressed air is cool there.